一、HLC长轴液下泵概述

HLC型立式长轴泵是在吸收国内外设计和制造经验的基础上,结合市场需求研制的成熟的系列产品。输送清水和含一定固体颗粒(如铁屑、砂粒、煤粉等)的污水、具腐蚀性工业废水、海水;输送液体温度不超过80℃。广泛用于原生水处理厂、污水处理厂、冶金钢铁行业(特别是该行业漩流池输送氧化铁皮)、电厂、矿山、市政工程及农田水利工程。

二、HLC型号意义

型号意义

300HLC2-50A

300—泵出口直径为φ300mm

HLC—立式长轴泵

2—叶轮级数为2级(级数为1时略)

50—设计点扬程为50m

A—叶轮外径切割代号

三、HLC长轴多级液下泵结构特点

HLC型立式长轴泵入口垂直向下,出口水平,单基础安装,泵和电机直联;从电机端俯视,泵为逆时针方向旋转,主要特点有:

1、用水力设计软件优化设计,性能优越,并充分考虑了叶轮及导叶的抗磨蚀性,使叶轮等易损件寿命大大提高;产品运行平稳、安全可靠、高效节能。

2、水泵进口装有滤网,开孔大小适当,既有效地防止大颗粒杂质进入泵内损坏水泵,同时又保证了净进水面积是扬水管断面面积的3.5倍以上,大限度地减少了进口损失,提高了水泵效率。

3、叶轮采用平衡孔平衡轴向力,叶轮前后盖板均设有可更换的密封环,保护叶轮及泵体。密封环采用特殊堰堤型结构,可有效防止泵停机后氧化铁皮或其它杂质沉至密封环间隙进口处,极大地提高了密封环和叶轮的使用寿命。

4、泵中间轴、扬水管和护管为多节,中间接轴采用套筒联轴专利技术,径向同轴度比其它联轴方式提高十倍,整机振动减少70%以上;扬水管数量可根据用户需要增减,适应不同的液下深度。叶轮、导叶体可为多级,适应不同的扬程要求。

5、水泵扬水管由法兰连接,中间有导轴承。水泵导轴承采用加强型填充聚四氟乙烯或加拿大赛龙轴承,也可采用丁腈橡胶(用于介质温度高于55℃),轴由护管保护。当输送清水时,可取消护管,导轴承不必接冷却润滑水;输送污水时,导轴承须外接冷却润滑水。对现场没有清洁水或清洁水成本较高的地方,可增设特殊结构,采用泵输送的介质经过过滤或沉淀分离后对导轴承进行冷却润滑。润滑水系统可增设流量及压力继电器等控制元件,开机前供水量低于额定供水量时,泵不能起动,当运行过程中由于某种原因(管路堵塞)造成缺水,缺压时,继电器发出报警信号,控制室蜂鸣器鸣叫,红灯报警,此时可打开旁通系统的阀门供水,保证供水充分,同时可对故障进行检修,这一控制系统可实现远程摇控。

6、泵的残余轴向力和转子部件的重量由电机座内的推力轴承承受或带推力轴承的电机承受。推力轴承用稀油润滑,并外接水进行冷却。推力轴承可埋设温控元件。

7、泵的轴封为填料密封,轴封及导轴承处装有可更换的轴套,以保护轴。叶轮的轴向位置由轴承部件上端或泵联轴器内的调整螺母来调整,十分方便。

8、水泵可配备控制柜,它具有根据液位自动启停和过载报警及实时远程监控等多种功能,可实现多泵联网远程集中控制。口径大于500mm的泵设有自动排气系统。

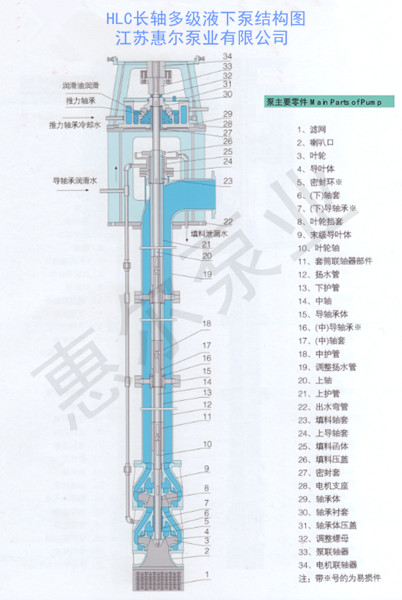

四、HLC长轴多级液下泵结构示意图

五、HLC性能参数表

|

参数 |

流量 |

扬程 |

转速 |

轴功率 |

电机 |

效率. |

泵重量 |

||

|

|

|||||||||

|

型号Type |

功率 |

型号 |

|||||||

|

|

|||||||||

|

m3/h |

l/s |

m |

rpm |

kw |

kw |

|

% |

kg |

|

|

150HLC-23 |

75 |

20.83 |

27.5 |

2980 |

7.8 |

18.5 |

Y160L-2 |

72 |

610+100N |

|

150 |

41.67 |

23 |

12.4 |

76 |

|||||

|

190 |

52.78 |

16.5 |

11.7 |

73 |

|||||

|

150HLC-30 |

75 |

20.83 |

36 |

2980 |

10.22 |

22 |

Y180M-2 |

72 |

620+100N |

|

150 |

41.67 |

30 |

16.35 |

75 |

|||||

|

190 |

52.78 |

24 |

17.5 |

71 |

|||||

|

150HLC2-46 |

75 |

20.83 |

55 |

2980 |

15.61 |

37 |

Y200L2-2 |

72 |

645+100N |

|

150 |

41.67 |

46 |

24.74 |

76 |

|||||

|

190 |

52.78 |

33 |

23.41 |

73 |

|||||

|

150HLC2-60 |

75 |

20.83 |

72 |

2980 |

20.4 |

45 |

Y225M-2 |

72 |

660+100N |

|

150 |

41.67 |

60 |

32.7 |

75 |

|||||

|

190 |

52.78 |

48 |

35 |

71 |

|||||

|

150HLC3-90 |

75 |

20.83 |

108 |

2980 |

30.7 |

75 |

Y280S-2 |

72 |

700+100N |

|

150 |

41.67 |

90 |

49.1 |

75 |

|||||

|

190 |

52.78 |

72 |

52.5 |

71 |

|||||

|

200HLC-19 |

190 |

52.78 |

22 |

1480 |

15.6 |

30 |

Y200L-4 |

73 |

900+170N |

|

300 |

83.33 |

19 |

20.2 |

77 |

|||||

|

360 |

100 |

15.8 |

21.5 |

72 |

|||||

|

200HLC-23 |

190 |

52.78 |

26.8 |

1480 |

19 |

37 |

Y225S-4 |

73 |

900+170N |

|

300 |

83.33 |

23 |

24.4 |

77 |

|||||

|

360 |

100 |

20.2 |

27.2 |

73 |

|||||

|

200HLC2-38 |

190 |

52.78 |

44 |

1480 |

31.2 |

55 |

Y250M-4 |

73 |

1020+170N |

|

300 |

83.33 |

38 |

40.3 |

77 |

|||||

|

360 |

100 |

31.6 |

43.1 |

72 |

|||||

|

200HLC2-46 |

190 |

52.78 |

53.6 |

1480 |

38 |

75 |

Y280S-4 |

73 |

1020+170N |

|

300 |

83.33 |

46 |

48.8 |

77 |

|||||

|

360 |

100 |

40.4 |

54.4 |

73 |

|||||

|

200HLC3-57 |

190 |

52.78 |

66 |

1480 |

46.8 |

75 |

Y280S-4 |

73 |

1140+170N |

|

300 |

83.33 |

57 |

60.5 |

77 |

|||||

|

360 |

100 |

47.4 |

64.6 |

72 |

|||||

|

200HLC3-69 |

190 |

52.78 |

80.4 |

1480 |

57 |

110 |

Y315S-4 |

73 |

1140+170N |

|

300 |

83.33 |

69 |

73.2 |

77 |

|||||

|

360 |

100 |

60.6 |

81.6 |

73 |

|||||

|

200HLC4-92 |

190 |

52.78 |

107.2 |

1480 |

76 |

132 |

Y315M-4 |

73 |

1260+170N |

|

300 |

83.33 |

92 |

97.6 |

77 |

|||||

|

360 |

100 |

80.8 |

108.8 |

73 |

|||||

|

250HLC-20 |

360 |

100 |

22.8 |

1480 |

30.2 |

45 |

Y225M-4 |

74 |

1200+250N |

|

480 |

133.3 |

19.8 |

32.8 |

79 |

|||||

|

540 |

150 |

17.8 |

34.9 |

75 |

|||||

|

250HLC-32 |

360 |

100 |

35.5 |

1480 |

47.1 |

75 |

Y280S-4 |

74 |

1280+250N |

|

480 |

133.3 |

31.5 |

52.5 |

78.5 |

|||||

|

540 |

150 |

29.1 |

58.7 |

73 |

|||||

|

250HLC2-40 |

360 |

100 |

45.6 |

1480 |

60.5 |

90 |

Y280M-4 |

74 |

1400+250N |

|

480 |

133.3 |

39.6 |

65.6 |

79 |

|||||

|

540 |

150 |

35.6 |

69.9 |

75 |

|||||

|

250HLC2-63 |

360 |

100 |

71 |

1480 |

94.2 |

160 |

Y315L1-4 |

74 |

1500+250N |

|

480 |

133.3 |

63 |

105 |

78.5 |

|||||

|

540 |

150 |

58.2 |

117.3 |

73 |

|||||

|

250HLC3-95 |

360 |

100 |

106.5 |

1480 |

141.2 |

220 |

Y315M1-4 |

74 |

1720+250N |

|

480 |

133.3 |

94.5 |

157.4 |

78.5 |

|||||

|

540 |

150 |

87.3 |

176 |

73 |

|||||

|

300HLC-25 |

540 |

150 |

27.5 |

1480 |

54.7 |

75 |

Y208S-4 |

74 |

1340+270N |

|

660 |

183.3 |

25 |

56.6 |

79.5 |

|||||

|

750 |

208.3 |

21.6 |

58.9 |

75 |

|||||

|

参数 |

流量 |

扬程 |

转速 |

轴功率 |

电机 Motor |

效率 |

泵重量 |

||

|

Date |

Capacity |

Head |

Speed |

Shaft |

Eff. |

Weight |

|||

|

|

Q |

H |

n |

power |

|

|

|||

|

型号 |

|

|

|

Pa |

功率 |

型号 |

|

|

|

|

Type |

|

|

|

|

Power |

Type |

|

|

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

m3/h |

l/s |

m |

rpm |

kw |

kw |

|

% |

kg |

|

300HLC-39 |

540 |

150 |

43 |

1480 |

85.5 |

132 |

Y315M-4 |

74 |

1480+270N |

|

660 |

183.3 |

39 |

88.8 |

79 |

|||||

|

750 |

208.3 |

35.6 |

97 |

75 |

|||||

|

300HLC2-50 |

540 |

150 |

55 |

1480 |

109.4 |

160 |

Y315L1-4 |

74 |

1580+270N |

|

660 |

183.3 |

50 |

113.1 |

79.5 |

|||||

|

750 |

208.3 |

43.2 |

117.7 |

75 |

|||||

|

300HLC2-78 |

540 |

150 |

86 |

1480 |

171 |

250 |

Y355M2-4 |

74 |

1780+270N |

|

660 |

183.3 |

78 |

177.6 |

79 |

|||||

|

750 |

208.3 |

71.2 |

194 |

75 |

|||||

|

350HLC-19 |

750 |

208.3 |

22.2 |

1480 |

60.5 |

90 |

Y280M-4 |

75 |

1540+270N |

|

900 |

250 |

19.3 |

58.4 |

81 |

|||||

|

1050 |

291.7 |

16.1 |

60.6 |

76 |

|||||

|

350HLC-30 |

750 |

208.3 |

33.5 |

1480 |

90.1 |

132 |

Y315M-4 |

76 |

1650+320N |

|

900 |

250 |

30.2 |

92 |

80.5 |

|||||

|

1050 |

291.7 |

25.5 |

98.6 |

74 |

|||||

|

350HLC-48 |

750 |

208.3 |

51.8 |

1480 |

143.1 |

200 |

Y315L2-4 |

74 |

1750+320N |

|

900 |

250 |

47.9 |

146.8 |

80 |

|||||

|

1050 |

291.7 |

42.5 |

162.1 |

75 |

|||||

|

350HLC2-60 |

750 |

208.3 |

67 |

1480 |

180.2 |

250 |

Y315M2-4 |

76 |

1920+320N |

|

900 |

250 |

60.4 |

184 |

80.5 |

|||||

|

1050 |

291.7 |

51 |

197.2 |

74 |

|||||

|

400HLC-25 |

1050 |

291.7 |

28.3 |

1480 |

106.6 |

160 |

Y315L1-4 |

76 |

2170+380N |

|

1320 |

366.7 |

25 |

109.7 |

82 |

|||||

|

1500 |

416.7 |

22 |

116.8 |

77 |

|||||

|

400HLC-39 |

1050 |

291.7 |

44.3 |

1480 |

169 |

250 |

Y355M2-4 |

75 |

2280+380N |

|

1320 |

366.7 |

39 |

172.1 |

81.5 |

|||||

|

1500 |

416.7 |

34.3 |

186.9 |

75 |

|||||

|

400HLC2-50 |

1050 |

291.7 |

56.6 |

1480 |

213.1 |

315 |

Y355L2-4 |

76 |

2520+380N |

|

1320 |

366.7 |

50 |

219.3 |

82 |

|||||

|

1500 |

416.7 |

44 |

233.6 |

77 |

|||||

|

400HLC-62 |

1050 |

291.7 |

68.5 |

1480 |

257.9 |

355 |

YLS4001-4 |

76 |

2650+400N |

|

1320 |

366.7 |

61.9 |

274.9 |

81 |

|||||

|

1500 |

416.7 |

56.6 |

308.5 |

75 |

|||||

|

450HLC-17 |

1500 |

416.7 |

19.7 |

980 |

104.6 |

132 |

Y315L1-6 |

77 |

2540+450N |

|

1740 |

483.3 |

17.4 |

98.8 |

83.5 |

|||||

|

1920 |

533.3 |

15.7 |

108.1 |

76 |

|||||

|

450HLC-27 |

1500 |

416.7 |

29.8 |

980 |

162.4 |

220 |

Y355L1-6 |

75 |

2650+500N |

|

1740 |

483.3 |

27.2 |

155.4 |

83 |

|||||

|

1920 |

533.3 |

25 |

169.9 |

77 |

|||||

|

450HLC-43 |

1500 |

416.7 |

46.2 |

980 |

245.3 |

315 |

YLS4003-6 |

77 |

2800+500N |

|

1740 |

483.3 |

43.1 |

249.2 |

82 |

|||||

|

1920 |

533.3 |

40.5 |

278.8 |

76 |

|||||

|

450HLC2-54 |

1500 |

416.7 |

59.6 |

980 |

324.8 |

400 |

YLS4005-6 |

75 |

3100+500N |

|

1740 |

483.3 |

54.4 |

310.8 |

83 |

|||||

|

1920 |

533.3 |

50 |

339.7 |

77 |

|||||

|

500HLC-20 |

1920 |

533.3 |

21 |

980 |

137.3 |

200 |

Y355M3-6 |

80 |

3600+900N |

|

2160 |

600 |

20 |

139.3 |

84.5 |

|||||

|

2400 |

666.7 |

17.8 |

147.4 |

79 |

|||||

|

500HLC-31 |

1920 |

533.3 |

34 |

980 |

222.4 |

280 |

YLS4002-6 |

80 |

4000+900N |

|

2160 |

600 |

31.4 |

220 |

84 |

|||||

|

2400 |

666.7 |

28.5 |

235.9 |

79 |

|||||

|

500HLC-50 |

1920 |

533.3 |

52.8 |

980 |

347.5 |

450 |

YLS4501-6 |

79.5 |

4300+900N |

|

2160 |

600 |

49.8 |

353.2 |

83 |

|||||

|

2400 |

666.7 |

46.1 |

386.5 |

77 |

|||||

|

参数 |

流量 |

扬程 |

转速 |

轴功率 |

电机 Motor |

效率 |

泵重量 |

||

|

Date |

Capacity |

Head |

Speed |

Shaft |

Eff. |

Weight |

|||

|

|

Q |

H |

n |

power |

|

|

|||

|

型号 |

|

|

|

Pa |

功率 |

型号 |

|

|

|

|

Type |

|

|

|

|

Power |

Type |

|

|

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

m3/h |

l/s |

m |

rpm |

kw |

kw |

|

% |

kg |

|

500HLC2-63 |

1920 |

533.3 |

68 |

980 |

444.7 |

560 |

YLS4503-6 |

80 |

4600+900N |

|

2160 |

600 |

62.8 |

440.1 |

84 |

|||||

|

2400 |

666.7 |

57 |

471.9 |

79 |

|||||

|

600HLC-25 |

2400 |

666.7 |

29.7 |

980 |

239.8 |

315 |

YLS4003-6 |

81 |

4800+1060N |

|

3000 |

833.3 |

25 |

238.8 |

85.6 |

|||||

|

3420 |

950 |

21.6 |

245.5 |

82 |

|||||

|

600HLC-39 |

2400 |

666.7 |

43.9 |

980 |

354.5 |

450 |

YLS4501-6 |

81 |

5340+1060N |

|

3000 |

833.3 |

39 |

375.1 |

85 |

|||||

|

3420 |

950 |

34.3 |

389.8 |

82 |

|||||

|

600HLC-62 |

2400 |

666.7 |

68.2 |

980 |

550.1 |

710 |

YLS5001-6 |

81 |

5340+1060N |

|

3000 |

833.3 |

62 |

599.2 |

84.5 |

|||||

|

3420 |

950 |

56.7 |

651.7 |

81 |

|||||

|

700HLC-20 |

3420 |

950 |

22.6 |

742 |

253.5 |

315 |

YLS4501-8 |

83 |

5230+1200N |

|

3900 |

1083.3 |

20.3 |

252.1 |

85.5 |

|||||

|

4380 |

1216.7 |

17.9 |

254.1 |

84 |

|||||

|

700HLC-32 |

3420 |

950 |

33.4 |

742 |

388.7 |

450 |

YLS4505-8 |

80 |

5440+1200N |

|

3900 |

1083.3 |

31.7 |

400.6 |

84 |

|||||

|

4380 |

1216.7 |

27.3 |

401.9 |

81 |

|||||

|

700HLC-50 |

3420 |

950 |

53.6 |

742 |

623.8 |

800 |

YLS5601-8 |

80 |

5760+1200N |

|

3900 |

1083.3 |

50.3 |

635.7 |

84 |

|||||

|

4380 |

1216.7 |

46.3 |

681.6 |

81 |

|||||

|

800HLC-24 |

4380 |

1216.7 |

27.4 |

742 |

398.4 |

500 |

YLS5001-8 |

82 |

6120+1380N |

|

5100 |

1416.7 |

24.3 |

401.6 |

84 |

|||||

|

5600 |

1555.6 |

22 |

419.2 |

80 |

|||||

|

800HLC-38 |

4380 |

1216.7 |

41.4 |

742 |

602 |

710 |

YLS5004-8 |

82 |

6340+1380N |

|

5100 |

1416.7 |

37.9 |

626.4 |

84 |

|||||

|

5600 |

1555.6 |

34.8 |

663.2 |

80 |

|||||

|

800HLC-60 |

4380 |

1216.7 |

64.8 |

742 |

953.9 |

1120 |

YLS6301-8 |

81 |

6670+1380N |

|

5100 |

1416.7 |

60.2 |

995 |

84 |

|||||

|

5600 |

1555.6 |

56.7 |

1054.1 |

82 |

|||||

|

900HLC-21 |

5600 |

1555.6 |

22.9 |

590 |

425.7 |

500 |

YLS5003-10 |

82 |

7120+1630N |

|

6300 |

1750 |

20.8 |

424.7 |

84 |

|||||

|

7000 |

1944.4 |

18.6 |

443 |

80 |

|||||

|

900HLC-33 |

5600 |

1555.6 |

35.1 |

590 |

652.6 |

800 |

YLS6302-10 |

82 |

7410+1630N |

|

6300 |

1750 |

32.6 |

665.6 |

84 |

|||||

|

7000 |

1944.4 |

29.7 |

707.4 |

80 |

|||||

|

900HLC-52 |

5600 |

1555.6 |

56.7 |

590 |

1073.8 |

1250 |

YLS6303-10 |

80.5 |

7820+1630N |

|

6300 |

1750 |

51.7 |

1081.3 |

82 |

|||||

|

7000 |

1944.4 |

48.3 |

1180 |

78 |

|||||

|

1000HLC-25 |

7000 |

1944.4 |

28.7 |

590 |

667.6 |

800 |

YLS5602-10 |

82 |

8240+1950N |

|

8400 |

2333.3 |

25.2 |

678.6 |

85 |

|||||

|

9400 |

2611.1 |

22.4 |

708.4 |

81 |

|||||

|

1000HLC-39 |

7000 |

1944.4 |

43.7 |

590 |

1029.1 |

1250 |

YLS6303-10 |

81 |

8510+1950N |

|

8400 |

2333.3 |

39.4 |

1061 |

85 |

|||||

|

9400 |

2611.1 |

35.1 |

1112.1 |

82 |

|||||

|

1000HLC-63 |

7000 |

1944.4 |

68.2 |

590 |

1606 |

2000 |

YL2000-10 /1703-1 |

81 |

8920+1950N |

|

8400 |

2333.3 |

62.6 |

1705.8 |

84 |

|||||

|

9400 |

2611.1 |

58.1 |

1860.3 |

80 |

|||||

|

1000HLC-63A |

6650 |

1847.2 |

61.6 |

590 |

1395.3 |

2000 |

YL2000-10 /1703-1 |

80 |

8920+1950N |

|

7980 |

2216.7 |

56.5 |

1480.3 |

83 |

|||||

|

8930 |

2480.1 |

52.4 |

1593.6 |

80 |

|||||

|

注:N为扬水管节数 |

|||||||||

公司实力 / ENTERPRISE STRENGTH

公司实力 / ENTERPRISE STRENGTH

1、量身定制

惠尔泵业可根据您的行业、要使用的场地及其他特殊需求,给您量身定制适合的产品类型。

2、专业生产

与华中理工大学、江苏大学合作开发新产品,快速适应市场需求,高品质完成各类(含特殊)泵类产品的设计制造。

3、专利保障

拥有教授级的专家团队研发设备,注重设备的效率、使用寿命,迄今为止设备获得发明专利认证众多。

4、服务周到

根据客户需求免费提供设备安装的图纸、调试、维护、后续跟踪,省内24小时上门解决服务需求,所有设备均享一年的质保期。

联系我们 / CONTACT US

联系我们 / CONTACT US - 江苏惠尔泵业有限公司

- 固定电话:400-0523-400 联系手机:18651142811(陈经理)

- 传真号码:0523-84332857邮箱:huier888888@163.comQ Q:791779336

- 门店地址:江苏省靖江市新桥镇工业园区

推荐资讯 / Recommended News

- 2019/12/18 渣浆泵机械密封失效的主要原因

- 2019/12/12 双螺杆泵的选型技巧

- 2019/12/2 脱硫泵的产品特点

- 2019/11/27 五大混流泵常见问题、解决办法

- 2019/11/25 钛材质的强制循环泵可用于哪些领域

- 2019/11/22 板框压滤机使用规则有哪些

- 2019/11/21 调节水泵流量的方式有哪几种

- 2019/11/20 CQB不锈钢磁力泵开机使用注意事项